To get robots to do things, computer scientists often use systems called physics simulators that reflect how a robot’s actions will impact the real world.

These simulators don’t work particularly well, however, when it comes to soft robots made of flexible, deformable materials. This is because the underlying physical laws of deformable objects are much more complicated, requiring a lot more computational power to simulate.

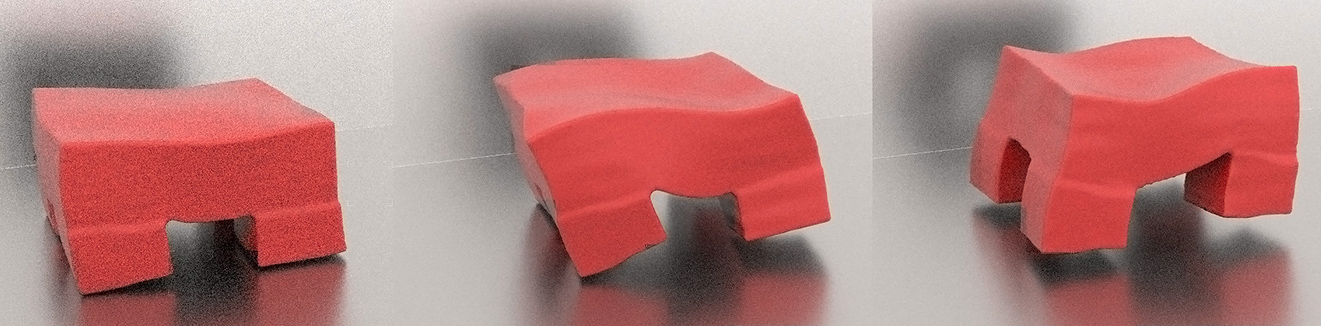

But in a new paper, a team from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) has developed a new simulator made specifically for soft robots, and have shown that it can realistically simulate an eclectic mix of robotic designs, from a crawling robot to a four-legged running robot.

The simulator doesn’t just efficiently evaluate robot designs, but also provides feedback on how designs can be improved. (The system’s feedback is computed based on something called “the chain rule,” and so the team has dubbed the simulator “ChainQueen”.) The team developed a high-performance GPU implementation of the simulator that they hope to eventually make open-source.

“We believe this system has the potential to dramatically accelerate the development of soft robots,” says PhD student Andrew Spielberg, one of the co-authors of the new paper being presented at the IEEE International Conference on Robotics and Automation (ICRA). “We’ve also created a TensorFlow interface that will allow users at all levels to develop their own soft robotics systems without needing to understand the simulator’s low-level details.”

ChainQueen builds off of existing techniques for simulating materials’ properties going back to the “Material Point Method” (MPM) which was used to create realistic snow in the film “Frozen”. Specifically, the new simulator uses a speedier form of MPM called MLS-MPM that’s based on the concept of “moving least squares” (MLS), and can be more seamlessly incorporated into inference, control and co-design systems. (MLS-MPM was developed by paper co-author Yuanming Hu and researchers at the University of Pennsylvania and UCLA.)

The new simulator takes MLS-MPM and makes it “differentiable,” meaning that the derivative, or direction of steepest descent, can be computed for all aspects of robot control and design. This means that numerical optimizers can efficiently search for optimal robot configurations and do so much faster than recent derivative-free approaches, such as reinforcement learning.

The team’s project focuses specifically on elastic designs, but Hu said that future work could simulate other materials, such as plastics, cloth, or fluids, or more complex interactions with rigid and soft environments.

Co-authors of the new paper include Hu, Spielberg, visiting student Jiancheng Liu, PhD student Jiajun Wu, and MIT professors Joshua B. Tenenbaum, William T. Freeman, Daniela Rus and Wojciech Matusik.